This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

New soft magnetic materials for a high-frequency future

Imagine tiny magnets powering our world, silently switching energy on and off in phones, cars, and even power grids. These unsung heroes are called soft magnetic materials. However, as devices become faster and more efficient, traditional materials struggle to handle the high frequencies needed by modern devices. Enter ASMCs, the new kids on the block.

These are amorphous soft magnetic composites (ASMCs) with some hidden potential. They are like metallic powders wrapped in a special coating packed with tiny air gaps and interfaces. This gives them superpowers like low power loss and flexible designs, making them super efficient at handling high frequencies.

But there is a catch—their magnetizations are not as high as traditional materials. So, scientists are on a mission to find the perfect balance between magnetic strength and softness. It's a puzzle worth solving for the future of our gadgets.

While ASMCs are fast, they're not very strong magnetically. It's like having a race car with a weak engine—fast but not powerful enough.

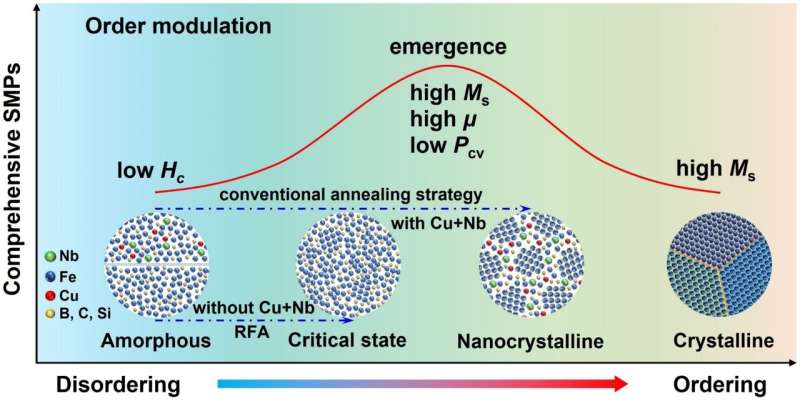

To address this issue, a group of Chinese scientists from Songshan Lake Materials Laboratory are using a cool trick called the "critical state" approach. Imagine applying a rotating magnetic field to these materials, like a potter shaping clay. This helps them crystallize just a little, creating tiny, super-efficient magnetic regions within them.

The result is a material that's both magnetic, strong, and efficient. This "critical-state" ASMC boasts features like:

- High magnetic strength: Like a powerful engine

- Low energy loss: Like a fuel-efficient car

- Works at high frequencies: Keeps up with the latest technology

This discovery is just the beginning. Scientists are working on further improvements using different coatings and shaping techniques for ASMCs, as well as exploring new materials altogether.

Prof. Haibo Ke said, "Such a strategy for constructing a critical-state amorphous alloy can allow us to develop novel ASMCs and promote the development of modern electronics, especially in high-frequency fields. In the future, on the one hand, the synergism of high permeability, low core loss, high magnetization, and high application frequency can be achieved through process optimization, such as using novel coating layers (magnetic and insulated) and new techniques in compaction."

"On the other hand, developing new powder compositions and modifying the intrinsic microstructure, such as the order modulation strategy and nanocomposites engineering, allow us to break the trade-off between 'magnetic strength' (saturation magnetization) and 'magnetic plasticity' (coercivity/core loss)."

"It is certainly possible to develop high-performance ASMCs and entirely soft magnetic materials, and the scientific community has already launched some activities that will promote the transform of the power electronics fields, especially the third-generation semiconductor-related devices."

These advancements will pave the way for more efficient electronics in everything from phones to power grids, ultimately powering a high-frequency future.

The findings are published in the journal Materials Futures.

More information: Liliang Shao et al, Critical state-induced emergence of superior magnetic performances in an iron-based amorphous soft magnetic composite, Materials Futures (2024). DOI: 10.1088/2752-5724/ad2ae8

Provided by Songshan Lake Materials Laboratory